- Products

- Services

- News & Event

- About Us

- Career

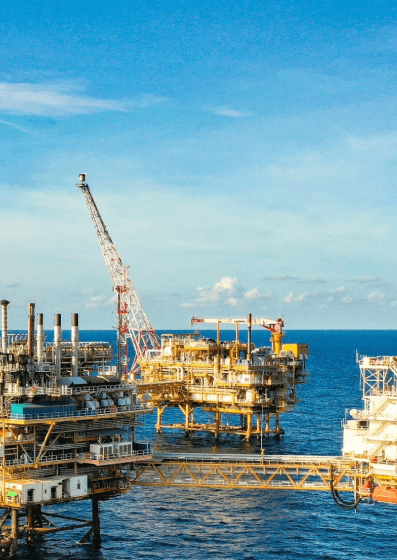

FLARE INSPECTION

Normally, the flare inspection need to shutdown the process and inspection need to climb up so high to reach the top of offshore oil and gas for asset inspection. Now with drone technology, they can use drones to capture pictures and process the inspection data via a platform. This can save so much time and cost that used to be spent on shutdown plant and flying a helicopter to do that manually. The Drone technology can increase the performance of inspectors and the business can do the asset inspection without shutdown the manufacturing process.

Inspecting a flare stack manually is a dangerous, time-consuming, and costly process. Especially, in the case of a shut down. An UAV survey means detailed images of the stack’s components without an inspector or engineer having to climb the stacks.

Highlight

CERTIFIED INSPECTION ASSISTED FOR RESULT ANALYSIS

Thermography survey by certified drone pilot

AI assisted for crack and corrosion analysis

Other Information

Flare stack inspection

- Visual and thermal inspection of flare stack

- Reduce asset downtime while inspection is performed online

- Reliability and cost efficiency with cost savings at 50-70% when compared with conventional inspection approach

- 5-7X faster than conventional inspection method

- AI-assisted for crack and corrosion detection

- Early detection of failures to extend the lifespan of flare stack

Benefits

Avoid Plant Shutdown: Prevent shutdowns, saving cost of production deferment.

Efficient Operations: 5-7X faster than traditional inspection methods for increased productivity.

Cost Savings: Achieve 50-70% cost savings compared to conventional inspection approaches.

Greener Operations: ZERO CO2 emissions, promoting environmentally friendly practices.

Use Cases