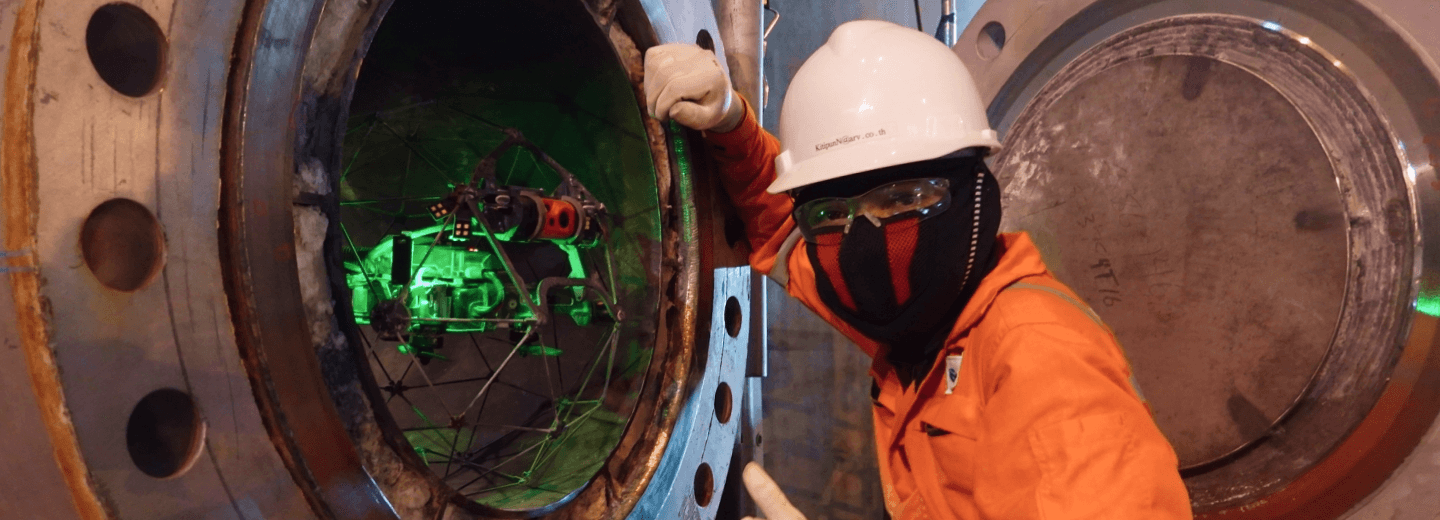

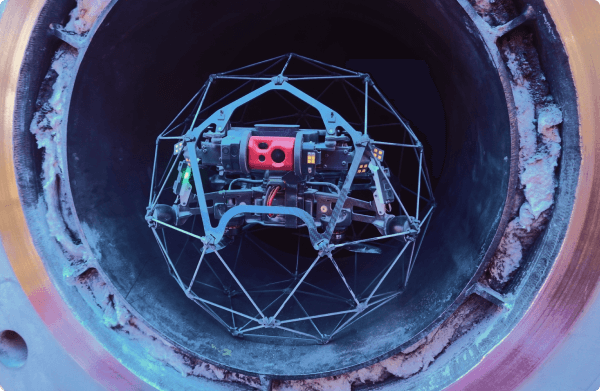

Confined Space Inspection

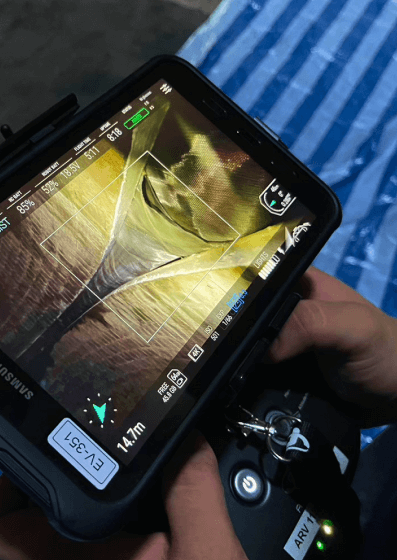

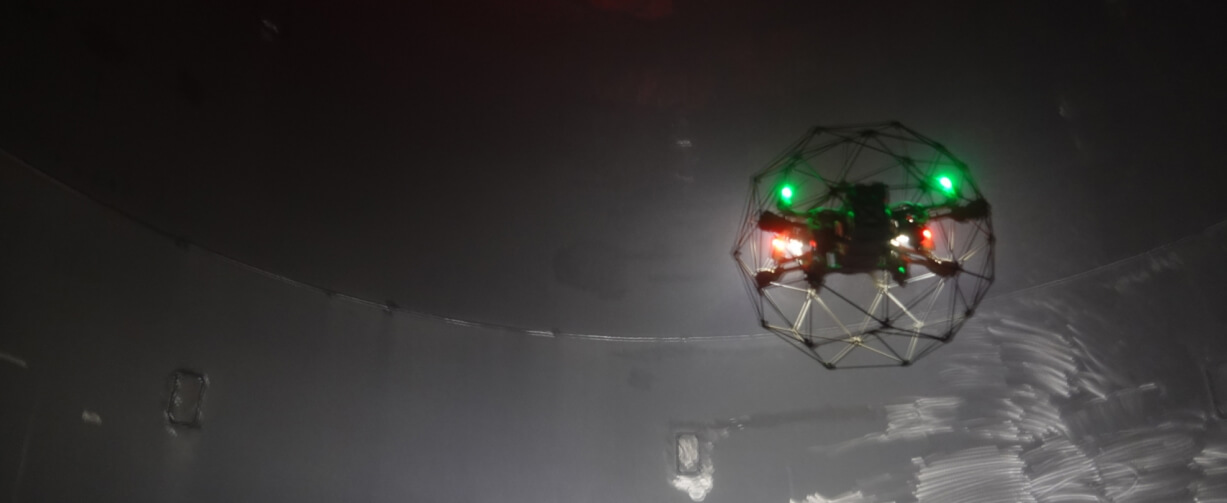

Skyller's Confined Space Inspection service leverages specialized drones designed for GPS-denied environments like storage tanks, wind turbines, and chemical tanks. This technology eliminates the need for human entry into dangerous areas, reducing inspection time by up to 80% and cutting costs by over 60%. With advanced AI and comprehensive reporting, Skyller provides safe, detailed, and efficient inspections of confined spaces, ensuring asset integrity and operational efficiency.

Highlight

Other Information

Additional Services

- Refractory Lining Crack Detection: Using drones to inspect and identify cracks or defects in confined spaces.

- Catalyst Erosion Monitoring: For precise identification of erosion in catalyst systems, reducing maintenance risks.

Benefits

80% Time Reduction

Inspection time reduced from 30 days to 5 days.

60% Cost Savings

Significant cost savings compared to traditional scaffolding methods.

Enhanced Safety

No need for human entry into hazardous confined spaces.

Detailed, Accurate Data

AI-driven analysis provides accurate and actionable insights.

Real-Time Reporting

Fast, comprehensive data delivered for smarter decision-making.

Regulatory Compliance

Ensures adherence to industry standards and local regulations.

Use Cases