Pressure Vessel Inspection

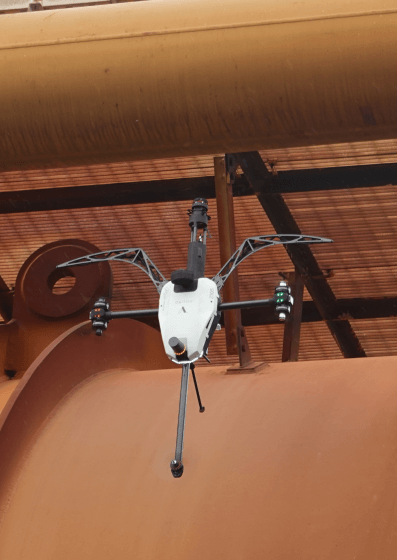

Skyller's Pressure Vessel Inspection service utilizes advanced drones equipped with AI analytics to conduct safe, efficient, and precise inspections. By minimizing downtime, eliminating the need for scaffolding, and reducing risks associated with manual inspections, Skyller ensures comprehensive visual assessments and accurate thickness measurements of pressure vessels. This service significantly lowers operational costs while enhancing safety and asset integrity.

Highlight

Other Information

Pressure Vessel Inspection Services

- Visual Inspection: Drone-based inspection for external visual assessments of elevated assets, piping, and hard-to-reach areas

- Ultrasonic Thickness Measurement: Drone-conducted UT inspections with advanced technology for precise thickness measurements, improving asset integrity and reducing risks

Benefits

- Zero scaffolding costs and reduced risk from working at heights

- Faster deployment and minimal downtime during inspections

- Accurate thickness measurements using EMAT and UT couplant technologies

- Significantly reduced inspection costs and man hours

- Comprehensive digital reporting with high-quality imagery and detailed analytics

Use Cases