STOCKPILE MONITORING

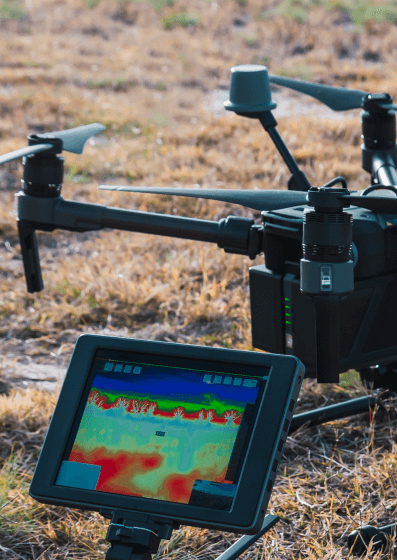

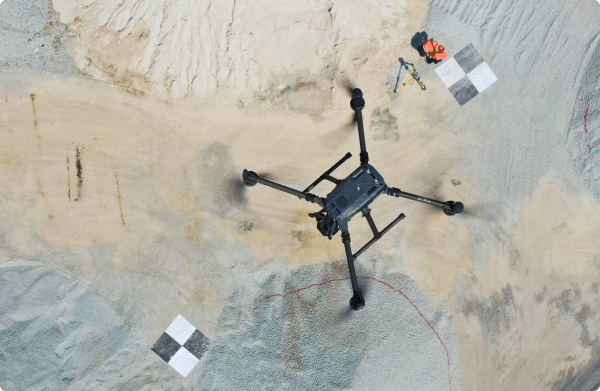

Our Stockpile Monitoring service uses advanced drone technology to accurately measure stockpile volumes, improving inventory management and material usage. By capturing detailed aerial images and integrating with inventory management systems, the service ensures precise calculations of material consumption in hot mix plants and offers real-time insights into stock levels. This helps companies optimize resource allocation, reduce operational costs, and maximize profitability.

Highlight

Other Information

Operational Benefits

Improved Measurement Accuracy

Advanced drone technology provides more accurate stockpile measurements compared to traditional methods, reducing errors in inventory management.

Cost Savings

Reduces manual labor and equipment costs by automating stockpile measurement, leading to cost-efficient operations.

Optimized Inventory and Material Usage

The system allows managers to track material consumption more efficiently, preventing overuse or shortages and maximizing profitability.

Enhanced Reporting and Forecasting

Generates detailed reports that support better monitoring of material needs and help forecast future usage requirements.

Real-Time Insights and Decision-Making

Real-Time Adjustments

Access to live data enables quicker responses to material shortages or overages, allowing for proactive adjustments.

Increased Efficiency

The system streamlines workflows, improving overall operational efficiency and reducing the time spent on manual measurement processes.

Use Cases